Pipeline testing services guarantee the dependability, effectiveness and safety of pipelines that move a variety of products across great distances. These services use innovative techniques to find leaks, obstructions or structural flaws before they become serious problems. Pipeline testing reduces environmental hazards and expensive downtime for industries that depend on continuous flow by identifying possible issues early. To comply with regulations and safeguard the public health the testing procedure complies with strict safety and quality standards. To thoroughly assess pipeline integrity professionals employ specialised technologies such as smart pigs, ultrasonic instruments and pressure tests. Services for pipeline testing are essential for preserving the robustness of infrastructure, increasing asset lifespans and improving operational efficiency. For sectors like water management, gas and oil, these services are essential.

Pipeline Pigging: Cleaning and Inspection Services

An essential procedure for keeping pipelines clean, functioning and operating efficiently is pipeline pigging. Through the use of specialised equipment known as pigs, pipelines are cleaned and inspected using this technique. Debris, accumulation and obstructions that can impede flow or result in over time structural damage are removed by cleaning pigs. Inspection pigs find corrosion, cracks and other flaws that jeopardise the integrity of pipelines. They are frequently outfitted with sophisticated sensors. Pigging pipeline maintenance allows enterprises to increase productivity, decrease downtime and successfully prolong asset lifespan. For accurate data gathering and analysis, modern pigging equipment employ advanced methods such as magnetic flux and ultrasonic testing. Pigging data helps find weaknesses so that repairs can be made quickly and environmental concerns from leaks are reduced. Pigging is essential to the oil, gas and water management industries in order to comply with strict safety and regulatory requirements. In addition to being a maintenance procedure pipeline pigging is a preventative measure that guarantees continuous material flow. To increase efficacy regular pigging schedules are adjusted to pipeline conditions including the substance being transported and environmental considerations. To properly oversee pigging operations and decipher the technical data produced operators need extensive training. This vital pipeline testing services keeps pipelines safe while shielding nearby ecosystems, communities and priceless resources from possible threats. A key component of contemporary pipeline management is pipeline pigging which strikes a balance between operational requirements and safety and environmental concerns.

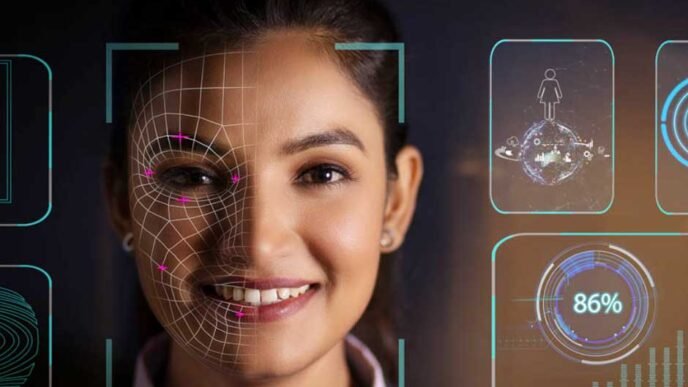

Impact of Artificial Intelligence in Pipeline Testing

Pipeline testing services has been transformed by artificial intelligence which improves precision, effectiveness and safety when maintaining vital infrastructure. AI analyses enormous volumes of data to find pipeline problems more quickly and accurately than conventional techniques. By spotting trends in pipeline behaviour machine learning algorithms are able to anticipate possible breakdowns before they become major problems. By implementing proactive maintenance operators may drastically lower environmental concerns and expensive downtimes because to this predictive capability. Drones and smart sensors are two examples of solutions powered by AI that effectively expedite pipeline inspections in areas that are hard to reach. These devices gather data in real time providing a thorough understanding of pipeline conditions without requiring operator intervention or stopping operations. To give accurate evaluations of pipeline integrity sophisticated AI systems examine corrosion rates, material fatigue and pressure fluctuations. Human mistake is eliminated by automated data analysis which guarantees that any possible problem is found and quickly resolved by professionals.

AI also makes it possible for operators to model different stress situations which improves pipeline performance in the face of shifting operational or environmental circumstances. By combining AI with pipeline testing regulatory criteria are better met and environmentally conscious enterprises are encouraged to adopt sustainable methods. Powered by AI digital twins virtually duplicate pipeline systems enabling deep risk analysis and testing without causing any physical disturbances. By reducing material degradation and successfully enhancing overall system reliability these creative methods increase pipeline lifespans. By producing actionable insights from complicated datasets for stakeholders in real-time scenarios AI also facilitates collaborative decision-making. Powered by AI remote monitoring lowers the need for on-site staff improving safety in dangerous situations or remote pipeline locations. Cloud technology and AI integration guarantees data accessibility enabling operators to react quickly to new threats.